Manufacturing is one of the industries where technology has grown pervasive. Industrial technology has evolved into a requirement for manufacturing companies to cut costs, eliminate waste, and boost profitability through processing equipment. The right equipment may significantly enhance your operations, productivity, innovation capability, and bottom line.

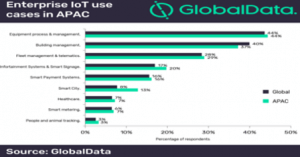

Global Data surveyed over 300 small, medium-sized, and large companies in APAC across a variety of vertical sectors, including manufacturing, utilities, retail, and healthcare. Global Data provides an in-depth insight into IoT (Internet of Things) perspectives of end-users, their investment plans, the choice of connectivity technology and suppliers, key advantages companies are hoping to gain, and the geographic range of deployment in its report.

In the study, equipment and management were the most frequent application cases in APAC across all of the sectors covered by the survey due to the direct financial advantages of operational efficiency.

However, to get those benefits from significant capital investment, you need a good and sound purchasing strategy that considers both your short and long-term needs. Whether you’re starting from scratch or your business needs to review its purchasing process, this article will explain key steps you should take.

Step 1: Assess Your Processing Equipment Needs

The first stage in the selection and purchase of processing equipment is to identify the business requirement. The cost of buying and installing capital equipment may be an enormous burden for any business. Before you make a move, try to assess the following questions:

- Will your business benefit from purchasing the processing equipment?

- How does this processing equipment fit into or meet your future business needs?

- ∙Does the need for processing equipment meet a safety need or regulatory requirement?

The search for processing equipment may be time-consuming and challenging if you don’t follow a defined process. Because product testing can’t be performed before purchase, choices are usually based on pricing, the credibility of the supplier, and design data.

Step 2: Make an Expenditure Plan

The operating expenses plan comprises new processing equipment. Still, it should also consider your current equipment’s scheduled downtimes and forecast end-of-life for you to prepare for replacement.

Whether you’ve done your capital expenditure plan and understood your equipment’s cycle periods, you’ll know if the latest model is a low-cost option. For some cost-effective tips, if you have a limited budget, you can purchase used processing equipment, such as a double cone blender and other equipment, at a very competitive price.

Manufacturers may also budget for essential maintenance data by connecting IoT-enabled gadgets to other devices through cloud or legacy systems via a range of sensor points, such as currents, voltages, vibrations, and temperatures. In this way, IoT transforms maintenance into a fast-paced, automated process capable of anticipating problems months in advance.

Step 3: Research for Reliable Suppliers

Following the creation of a comprehensive specification of your business needs and expenditure plan, the third stage in selecting and purchasing process equipment is to assess the available suppliers. This phase starts with the distribution of your specification to the most competent vendors found.

Consider the following when selecting a provider to help you minimize repairs, maintenance, and safety risks.

- When selecting a manufacturer of food processing equipment, look for experience with your business.

- Product testing with your manufacturer of processing equipment enables you to solve any issues before becoming problems in your facility.

- A list of references should be sent to your equipment manufacturer, including a contact person whom you can question about the processing equipment.

- While specific standard fittings may work for your procedure, you should be able to customize some processing equipment elements without much difficulty. You may want to add or delete some features, add coatings or finishes, or change the machine size to suit your facility.

- You may wish to examine the manufacturer’s facility to select the best processing equipment, manufacturer. This will allow you to understand better how the manufacturer does business, including the production equipment and technologies they employ, the facility’s condition, capacity, and compliance with safety regulations.

You can check the list of Asia-Pacific businesses and startups (APAC) in the equipment manufacturing area includes statistics on their history of financing, investments, and acquisition patterns.

Step 4: Negotiate Your Contract Terms with Your Chosen Supplier

The negotiation of a contract is a process of negotiating with suppliers on an arrangement that benefits both sides. This often leads to reduced pricing and more significant product volumes (or expectations of future sales). The objectives of these discussions are simple:

- All criteria are well defined

- Goods and services must be identified

- Both sides have expectations, including time limits, quality, etc.

- Risks and obligations are highlighted

- Compensation, including payment schedule, conditions of financing, and total cost, is fully stated

- Dates of renewal, completion, and termination, and delivery dates agreement

Negotiating without adequate presentation will always lead to failure. You may enter into a contract, but the probability of better pricing or better terms is low. You must know this supplier and its rivals. Find out how pricing compares to the market, what the supplier charges to provide the processing equipment.

Conclusion

The suitable investment in the appropriate equipment and tools for work is one of the greatest methods to save costs. It’s because one of the costly business expenses is the maintenance and repair of your processing equipment. It’s essential to establish a sound purchasing procedure in your processing equipment to reduce your company expenses significantly.

Recognising excellence across the Asian Pacific.

Nominate now ➜

Read the latest and past issues of APAC Insider.

Explore issues ➜

Find out how we can help your business grow.

Find out more ➜